- PDF Catalogue

- Extranet

-

- You are here:

- Technical Help >

- Safety Standards

Safety Standards

WARNING

The gas cylinders contain high pressure gas. The rules detailed below are mandatory.

Any unauthorized operation performed, or improper use can cause serious material or personal injury.

NITROGAS is not responsible for personal injury and damage that may happen because of violation of such security rules.

The highest risk of accident is a direct consequence of the internal gas pressure in the gas spring that in the case of misuse, improper handling or failure to follow safety rules, can cause unexpected and uncontrolled output of any component of the gas cylinder. If there is any suspicion of damage to the cylinder, immediately remove it.

1. Maintenance must be performed exclusively by personal that has been trained and certified by NITROGAS. Any improper handling could cause serious safety hazards or limit the lifetime of the gas springs.

Before any repair, discharge the pressure and ensure that the rod is completely within the body.

2. During discharge of the gas spring, orientate the gas flow in the opposite direction to the operator and position the discharge point as high as possible.

We recommend the use of eyewear.

Avoid potential free output of the rod to the outside.

3. Gas cylinders must only be charged with commercial nitrogen.

The maximum charge pressure (at 20 ° C) is marked on each gas spring. Do not exceed the maximum charge pressure without the prior written consent of NITROGAS.

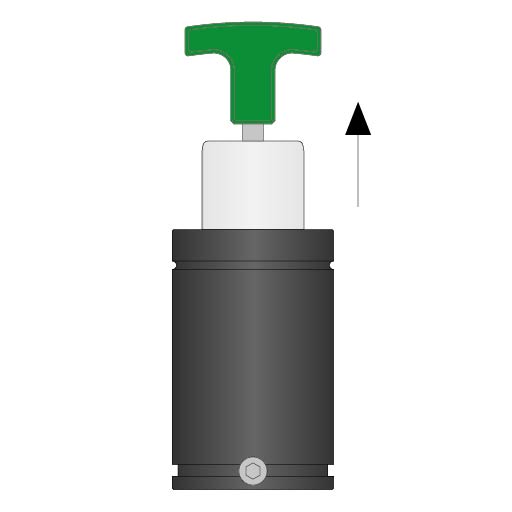

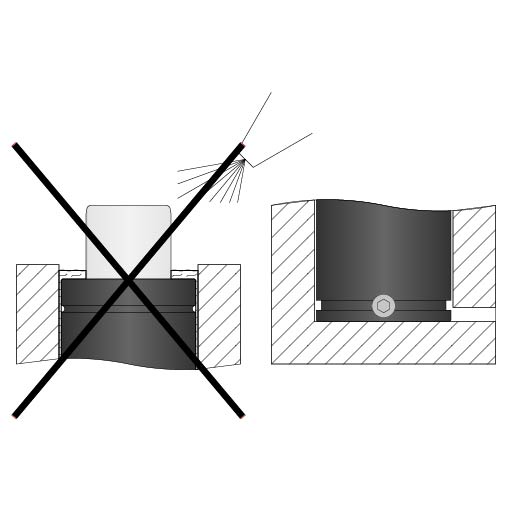

4. Before loading any gas spring, ensure that the piston rod is in its most extended position and the safety ring (in case any) is perfectly located in the housing.

This operation ensures that in a later process of loading, the shaft is not free and will not take off.

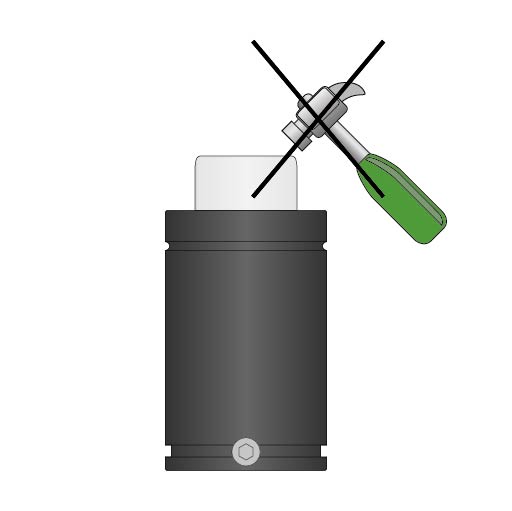

5. To test the force of a gas spring, there are specific tools for measurement to be used. Never hit on the piston rod to see if the cylinder is under pressure.

If you do it and the cylinder is loaded, it may cause a violent outcome of the rod exceeding the resistance limits of the product and escape externally, with the consequent risk of accident.

6. We recommend a regular visual inspection of the gas springs.

If a gas cylinder has damage to its structure, discharge the pressure prior to review.

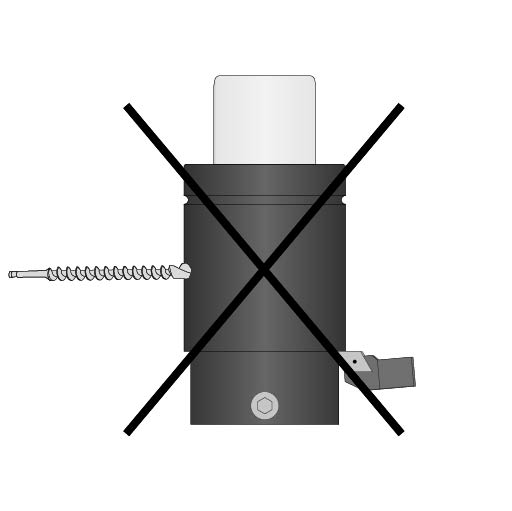

7. Any secondary operations (including grinding, machining, or welding) any part of the gas spring is completely forbidden.

The risks increase if operations are performed with a loaded gas cylinder.

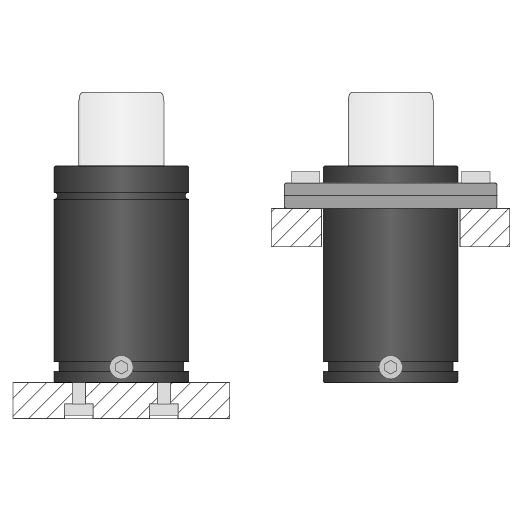

8. Gas springs must only be installed in the tool in the ways described in the specification sheet for each model.

The gas springs shall be securely held in place by the thread of the bottom of the body or by fastening accessories NITROGAS offers in each model.

If the cylinder is released from its location, it can easily produce a crushing force and subsequent explosion resulting in a clear risk of accident.

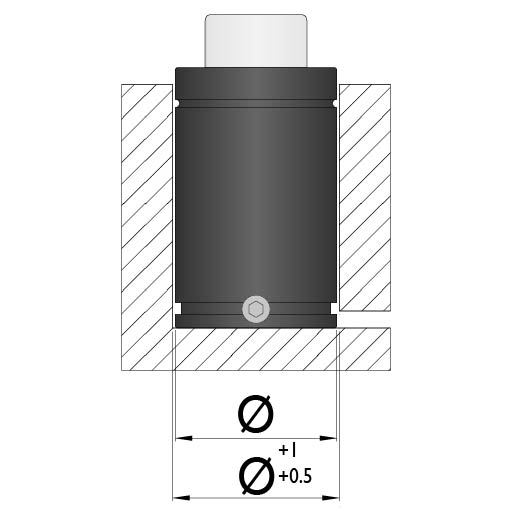

9. In the case of accommodating the gas spring in a pocket drilled in the tool, the body must be adjusted to the hole to prevent from pitching.

If the gas spring is housed in a pocket that can be flooded, please allow for drainage to facilitate the outlet of fluids.

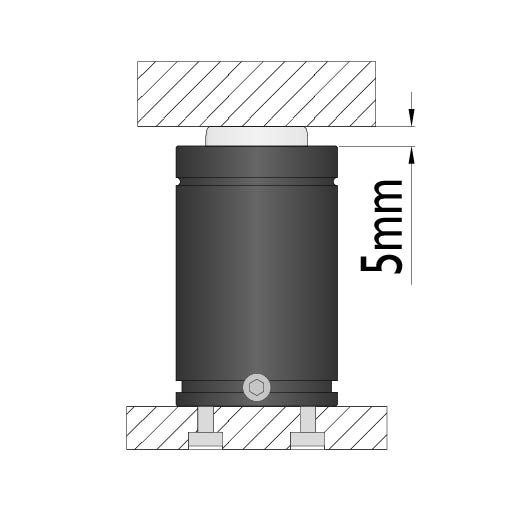

10. Avoid using the last 5mm of the gas spring stroke to prevent possible over-stroke caused by changes or errors in the tool.

An excessive stroke can have serious and obvious security risks that can cause permanent damage to the gas spring.

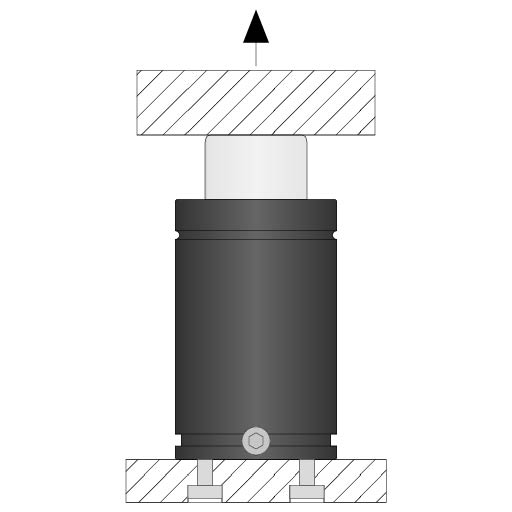

11. Prevent the output piston rod is sudden or uncontrolled. Do not exceed the maximum speed specified in the file for each model.

12. Protect the gas springs from direct contact with liquids or solids contaminations.

If the gas cylinder is housed in a pocket that can be flooded, include drains to facilitate any outlet of fluids.