- PDF Catalogue

- Extranet

-

- You are here:

- Technical Help >

- Maintenance recomendations

Maintenance recomendations

Maintenance must be carried out exclusively by personal that has been trained and certified by NITROGAS. Any improper handling could cause serious safety hazards or limit the lifetime of the gas springs.

1. Before any repair, discharge entirely the pressure and ensure that the rod is completely within the body.

2. We recommend a regular visual inspection of the gas springs.

If a cylinder has damage to its structure, fully discharge the pressure prior to review.

3. During unloading of the gas spring, direct the flow of gas away from the operator and position the discharge point as high as possible.

We recommend using safety glasses.

4. Never throw away the gas cylinder without having properly discharged the pressure.

5. Gas cylinders must be loaded with commercial nitrogen.

The maximum loading pressure (at 20 ° C) is marked on each cylinder.Do not exceed the maximum charge pressure without the prior written consent of NITROGAS.

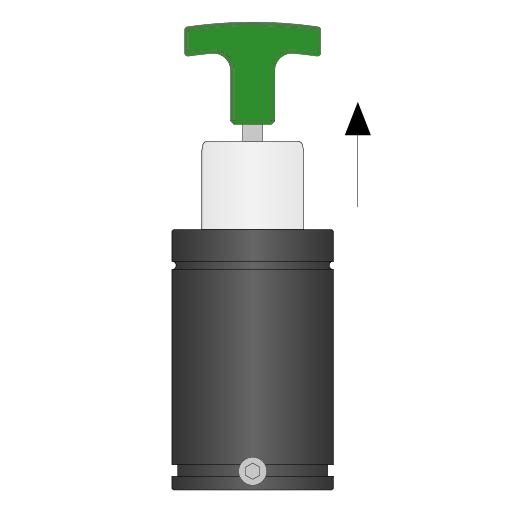

6. Before loading any cylinder, make sure that the rod is in its most extended position and the safety ring (in case any) is perfectly located in the housing.

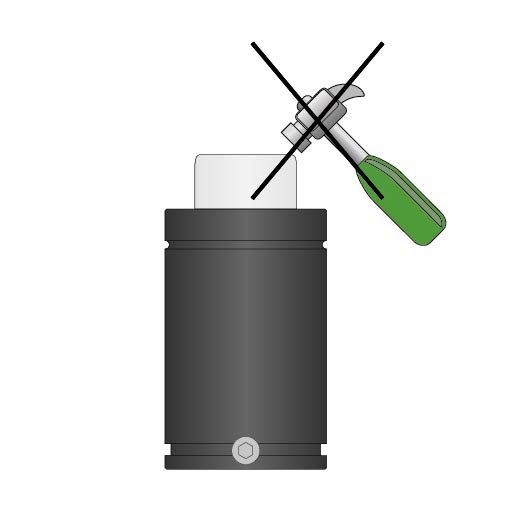

7. To test the strength of a specific cylinder there are specific tools for measuring the force. Never hit the piston rod to see if the cylinder is under pressure.

The hardness of the contact surface should be sufficient.

Ensure full contact on the bearing surface of the rod.

8. To ensure correct operation of the cylinder, the surfaces of the rod and body of the cylinder must remain free of blows, scratches, or any type of deformation.

The secondary operations of any part of the cylinder (including rinding, machining, welding, etc) is completely forbidden.

9. Protect cylinders during transportation. Protect cylinders from hitting each other; protect them from oxidation in the case of maritime transport.