- PDF Catalogue

- Extranet

-

- You are here:

- Technical Help >

- Specifications for installation and use

Specifications for installation and use

For proper operation, gas springs must be installed following the specifications for installation and use described below.

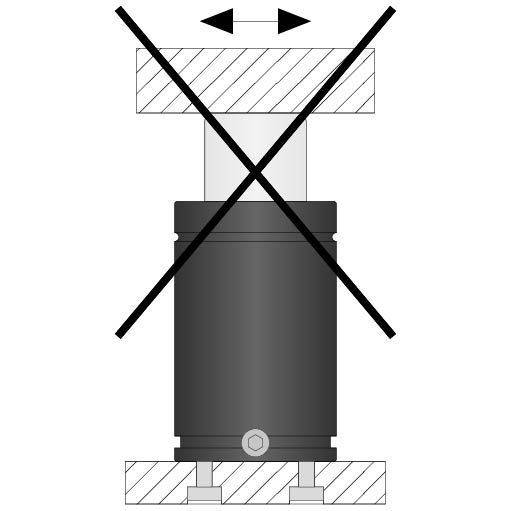

NITROGAS is not liable for damages or premature wear caused to gas springs, due to failure to comply with these specifications for installation and use.

Gas spring life is directly related to the existence of lateral forces. Improper installation is the direct cause of lateral forces and therefore has implications in the premature deterioration of the product. Pay special attention to the proper clamping of the product and the total adjustment of the bearing surface of the rod

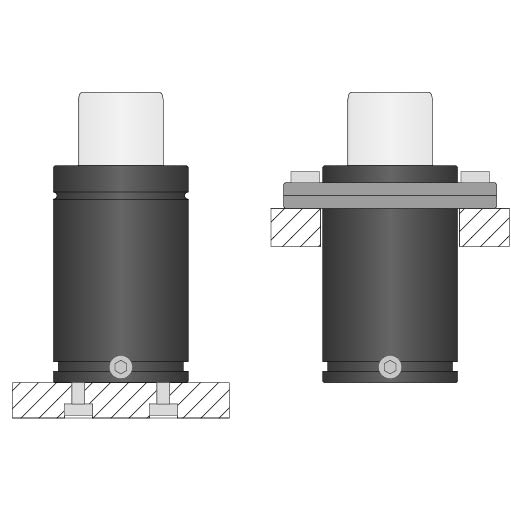

1. Install gas springs in the tool only in the ways described in the specification sheet for each model.

Gas cylinders must be securely fastened by the threads of the bottom of the body or by fastening the accessories NITROGAS offers for each model.

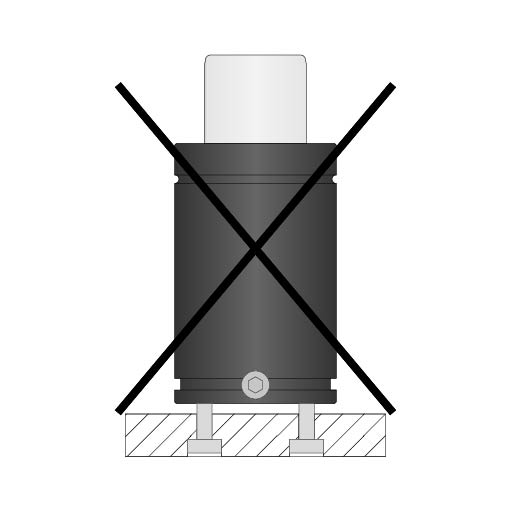

2. Check that the length of the fastening screw used is adequate so that the settlement of the cylinder is always on its base.

Tighten the clamping screws holding the base of the cylinder to the recommended torque: M6 = 10 Nm, M8 = 24nm, M10 = 45Nm, M12 = 80Nm. 3.

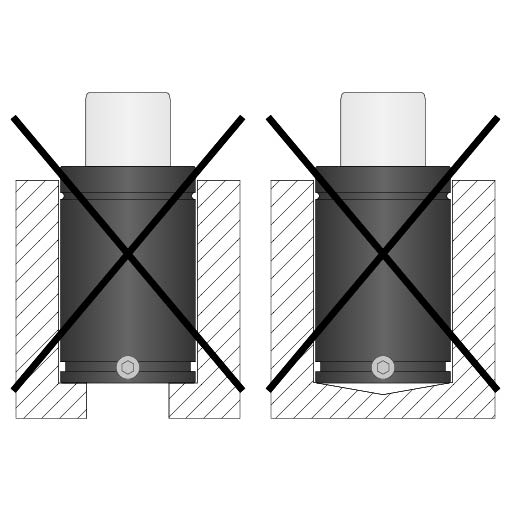

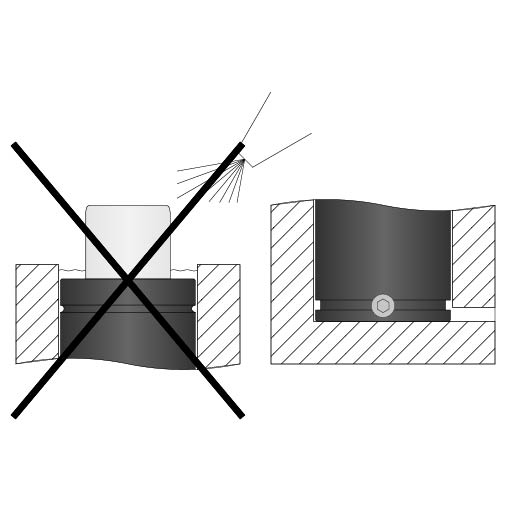

3. The base of the gas spring must rest on a plane support. Inadequate housing can damage the gas spring or reduce its life.

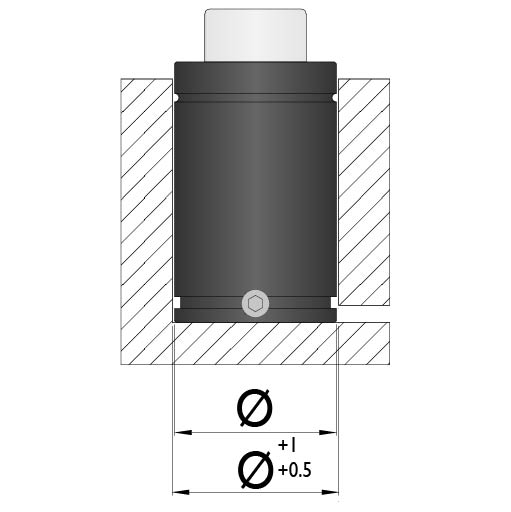

4. In case of accommodating the gas spring in a drilled pocket in the tool, the body must be adjusted to the hole to prevent from pitching.

5. Protect gas springs from liquid or solid contamination.

If the gas cylinder is housed in a pocket that can be flooded, include drains to facilitate any fluid outlet.

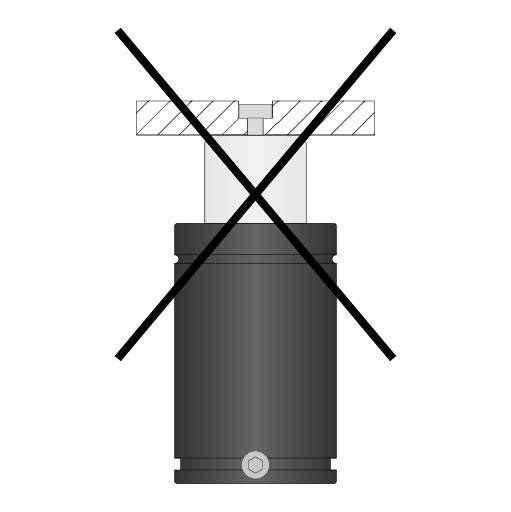

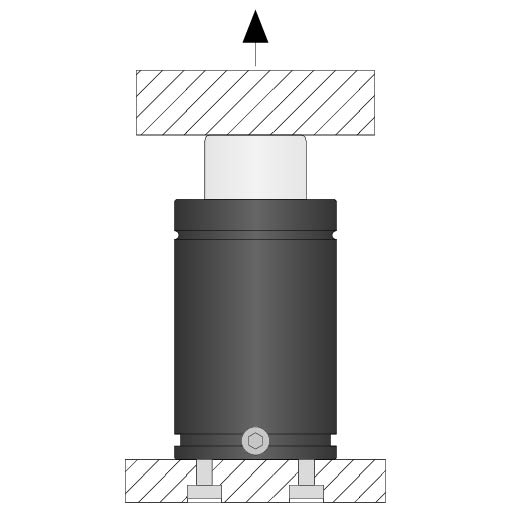

6. Do not use the threaded holes in the rod end to tie the gas spring to the tool.

This hole is only intended for maintenance. Do not use for transport operations of gas springs.

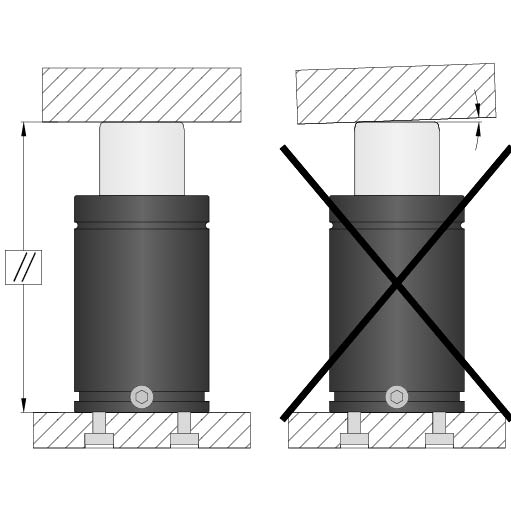

7. Ensure parallelism between the surface of the gas spring and the rod pushing surface to prevent the occurrence of lateral forces.

The hardness of the contact surface should be sufficient.

Ensure full contact on the bearing surface of the rod.

8. Avoid any lateral displacement of the gas spring while running. Give special attention to any vibrations during movement of the rod.

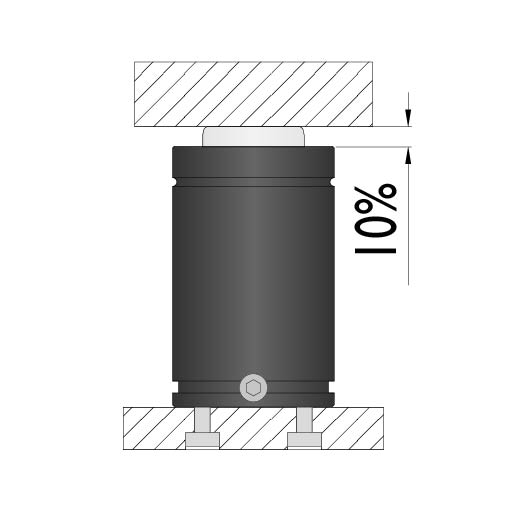

9. It is recommended to provide a reserve of travel at least 10% of the nominal stroke.

The recommended reserve of travel for each gas spring is indicated in the specification sheet for each model.

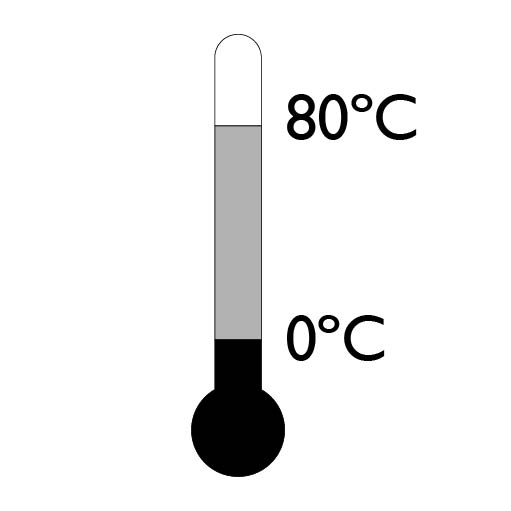

10. The operating temperature of the gas springs is between 0 º C and 80 ° C. Upon request NITROGAS can supply gas cylinders supporting temperatures between - 20 ° C and 180 ° C.

11. Prevent the sudden or uncontrolled rod output. Do not exceed the maximum speed specified in the file for each model.